"Factory AI helped us identify developing faults early enough to plan work, secure spares, and avoid unplanned downtime. It's shifted us from reacting to failures to acting with confidence."

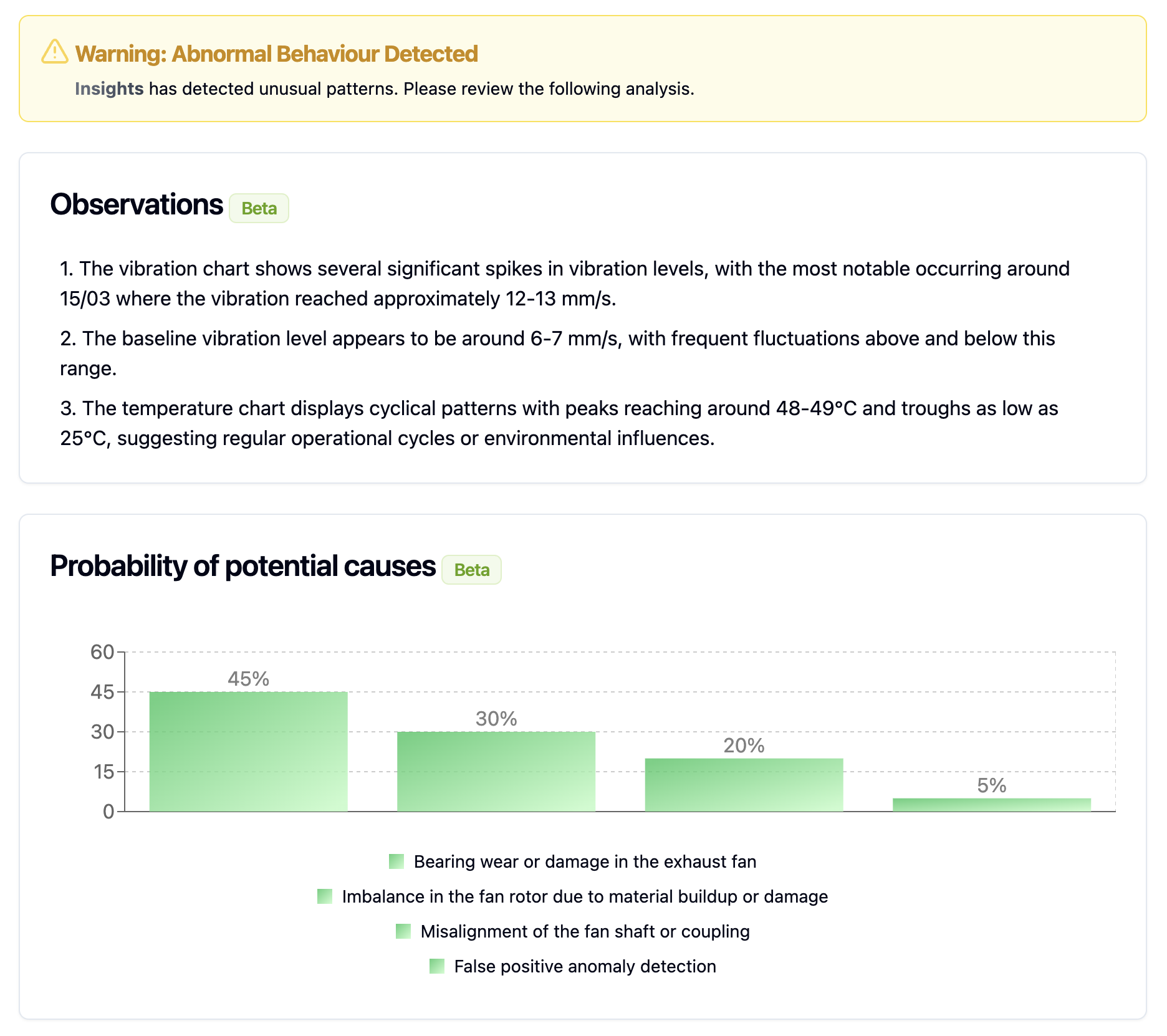

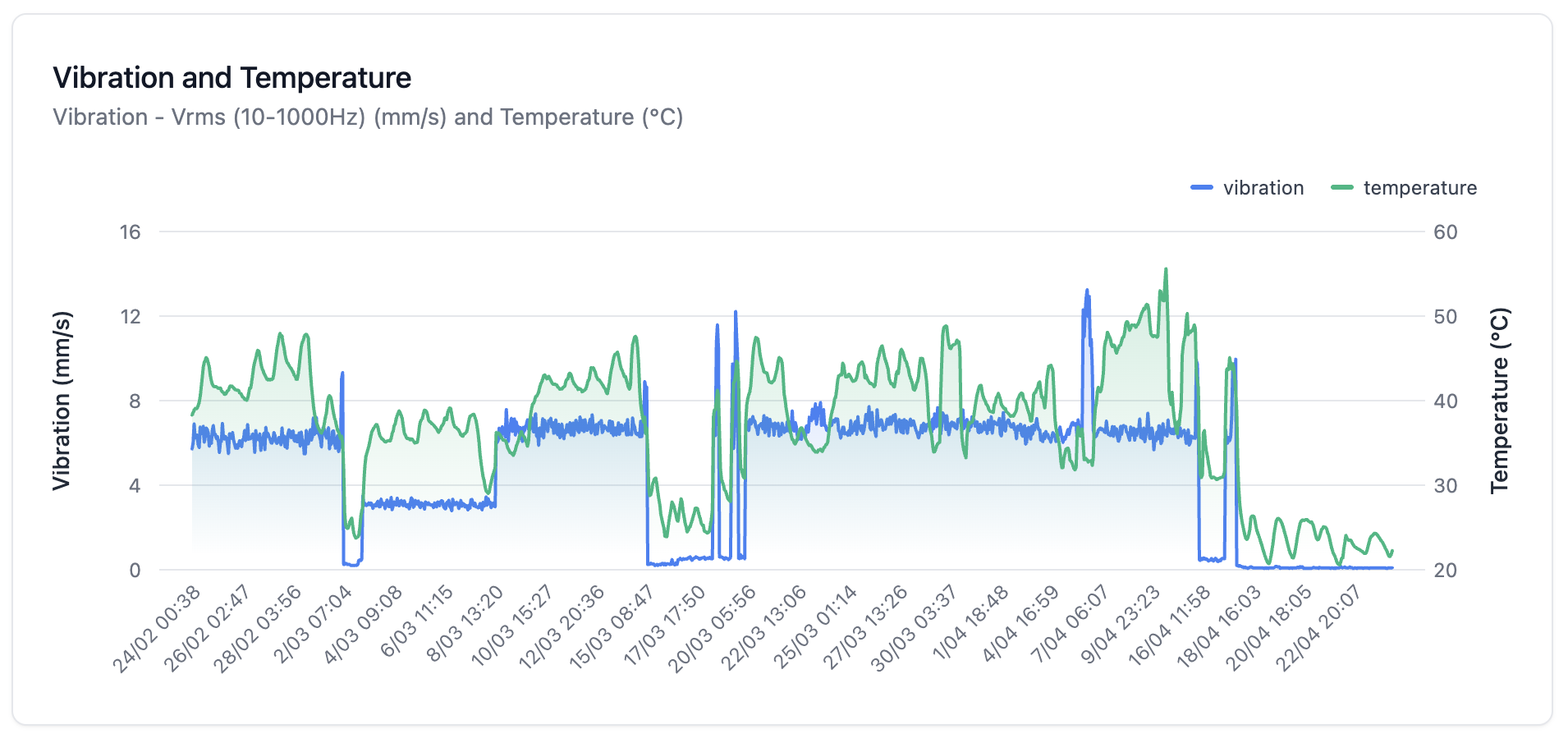

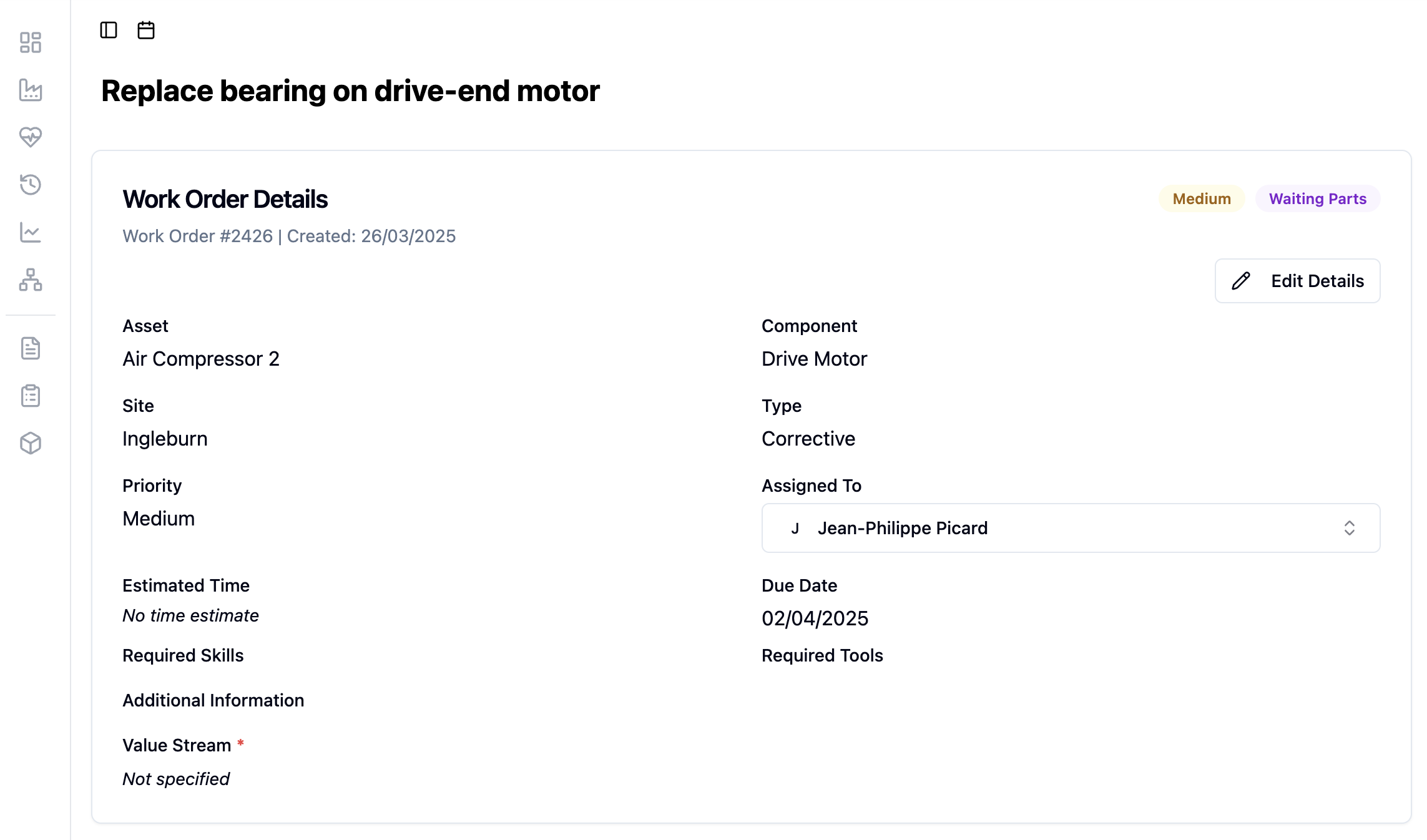

Across two high-throughput food manufacturing sites, Factory AI enabled early detection of emerging faults so maintenance teams could inspect assets before failure and execute planned interventions.

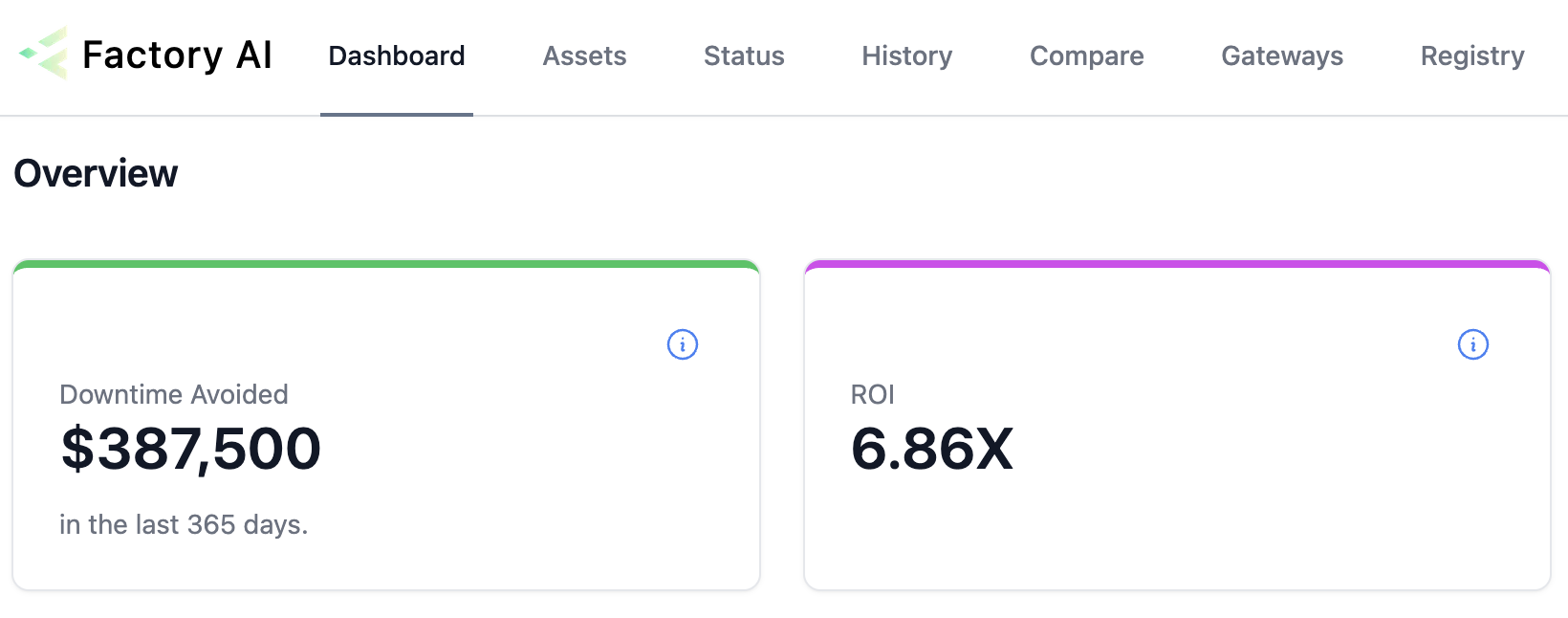

Over 12 months, ~80 actionable predictive alerts helped teams reduce reactive work, improve maintenance prioritization, and support an estimated ~$500,000 in avoided downtime.

Reliability Engineer

Arnotts