TRUSTED AND SUPPORTED BY

Optimize maintenance with AI-powered scheduling

Prevent uses advanced algorithms to create optimal maintenance schedules that balance equipment reliability with operational efficiency.

Proactive maintenance planning

Schedule maintenance tasks based on equipment condition, usage patterns, and failure predictions to prevent unexpected breakdowns.

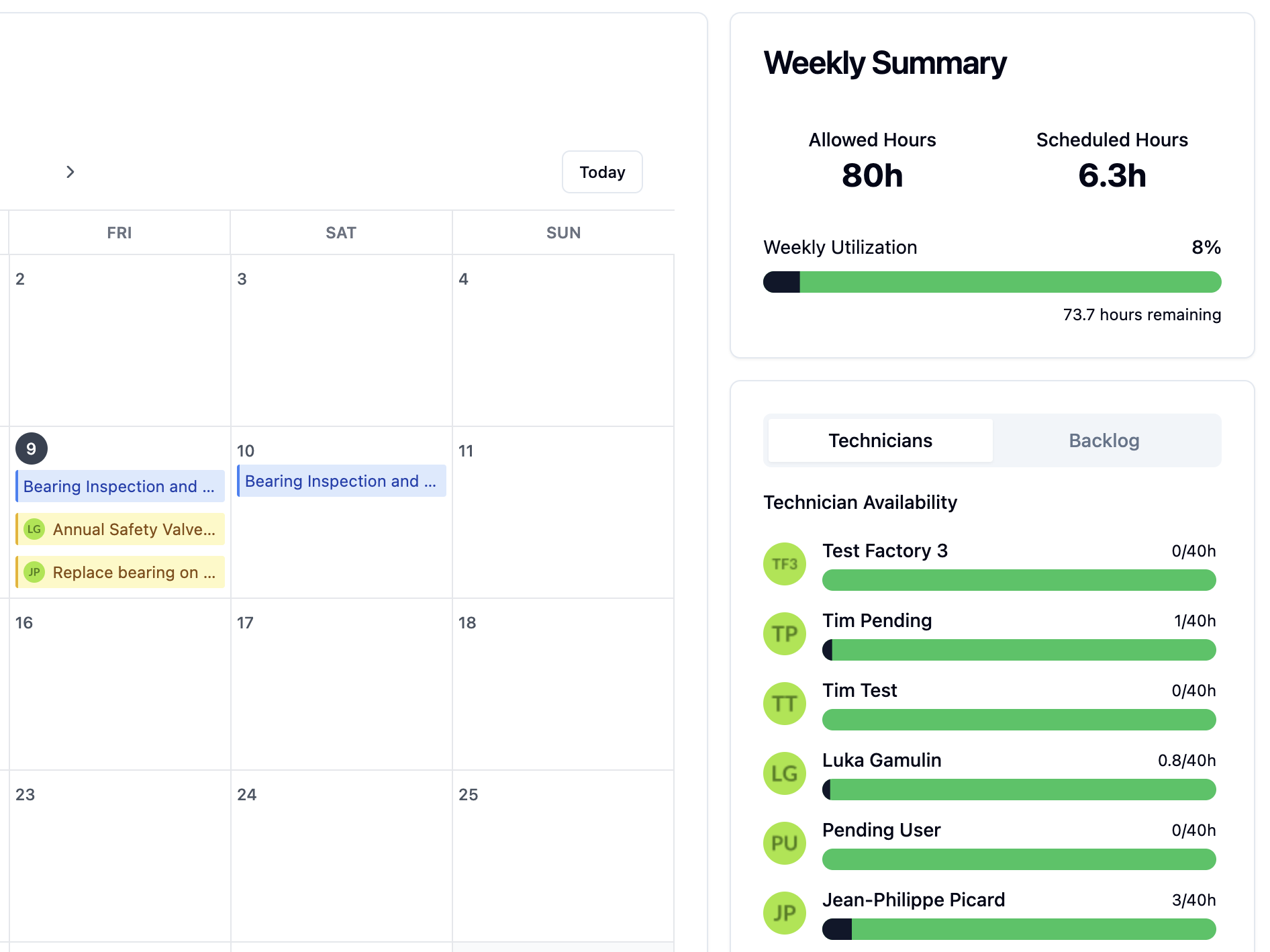

Resource optimization

Efficiently allocate maintenance resources and minimize downtime by coordinating tasks across your facility.

Comprehensive maintenance management

Prevent provides all the tools you need to implement and maintain an effective preventive maintenance program.

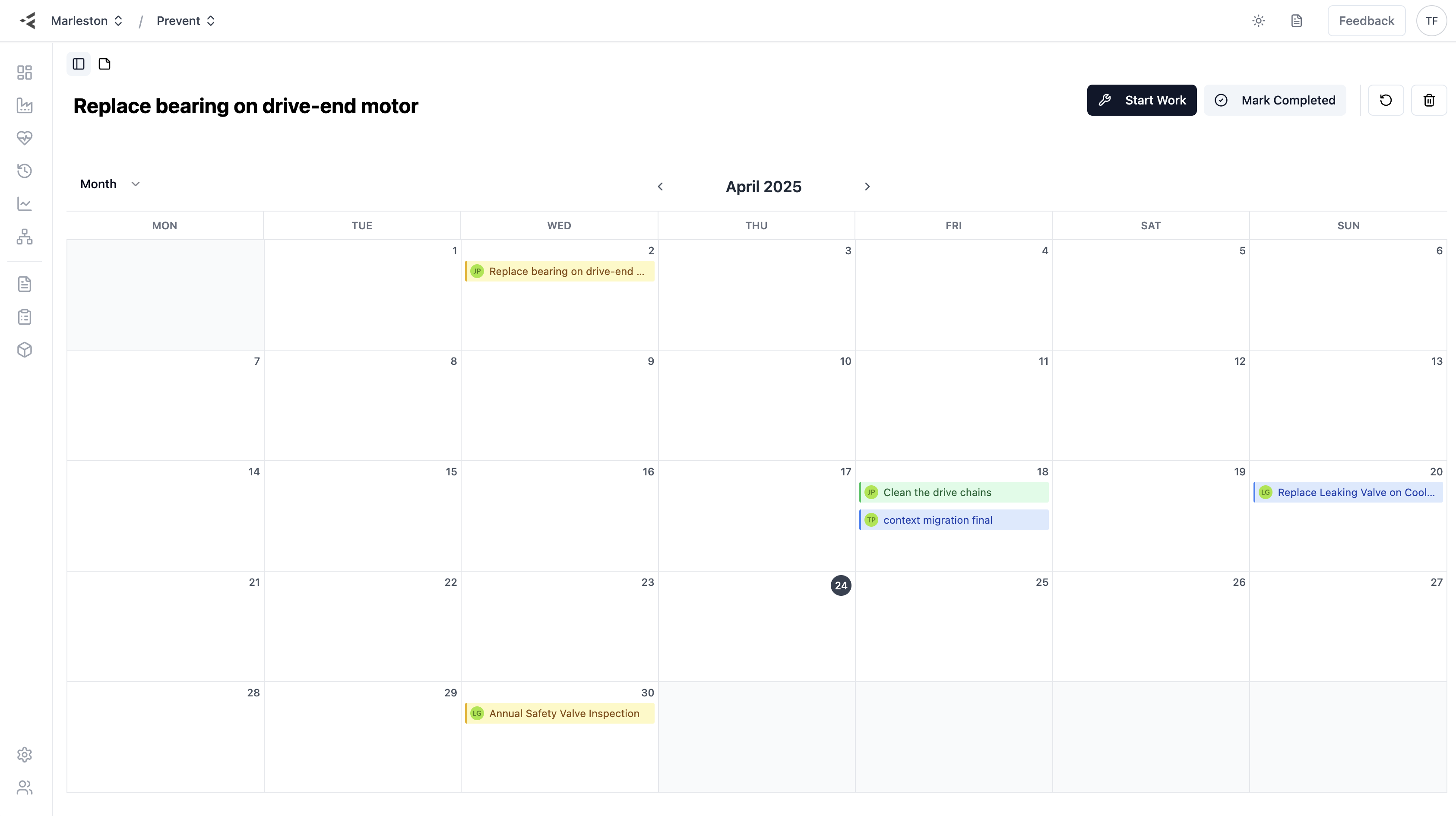

Smart Scheduling

AI-powered maintenance scheduling that adapts to your operational needs and equipment conditions.

- Dynamic task prioritization

- Resource availability tracking

- Automated schedule optimization

Mobile Maintenance

Empower your maintenance team with mobile tools for efficient task execution and real-time updates.

- Offline task access

- QR code scanning

- Photo and note capture

Compliance & Safety

Ensure regulatory compliance and maintain safety standards with built-in checks and documentation.

- Safety checklist integration

- Compliance reporting

- Audit trail maintenance

Proven results for maintenance teams

Prevent helps maintenance teams achieve significant improvements in efficiency and equipment reliability.

Increase in maintenance efficiency

Reduction in emergency repairs

Return on investment

Weeks to implementation

Factory AI Prevent FAQ

Common questions about our AI-first CMMS platform.

How does Prevent help optimize maintenance schedules?

Can Prevent integrate with our existing systems?

What types of maintenance tasks can Prevent help with?

How quickly can we implement Prevent?

Does Prevent include predictive maintenance?

Is Prevent suitable for mid-sized manufacturers?

Are there maintenance platforms that combine predictive analytics with a full CMMS in one system?

Which platforms provide strong reporting on maintenance KPIs like response time and completion rate?

Ready to transform your maintenance operations?

Contact our team to schedule a personalized demo and discover how Prevent can help your organization optimize maintenance schedules and prevent equipment failures.